Akanksha Sharma 2025-08-20

When it comes to enhancing product performance and operational reliability, material choice is everything and butyl rubber is fast becoming the preferred elastomer across India’s industrial sectors. Its standout feature, airtightness that’s up to 10 times better than natural rubber, makes it invaluable in applications ranging from automobile tires to medical-grade packaging.

Beyond air retention, butyl rubber also boasts strong resistance to chemicals, heat, and ozone, making it a prime choice for environments that demand both durability and precision. The material’s adaptability is now drawing attention in India’s evolving sectors such as EV mobility, pharma manufacturing, and green construction. With the global butyl rubber market valued at USD 3.7 billion in 2023, India is poised to claim a larger share of that growth.

Let’s take a deep dive into how butyl rubber is processed and its role in India’s next wave of industrial innovation.

Producing butyl rubber is a highly technical process designed to deliver specific performance attributes. Here’s a look at how it’s done:

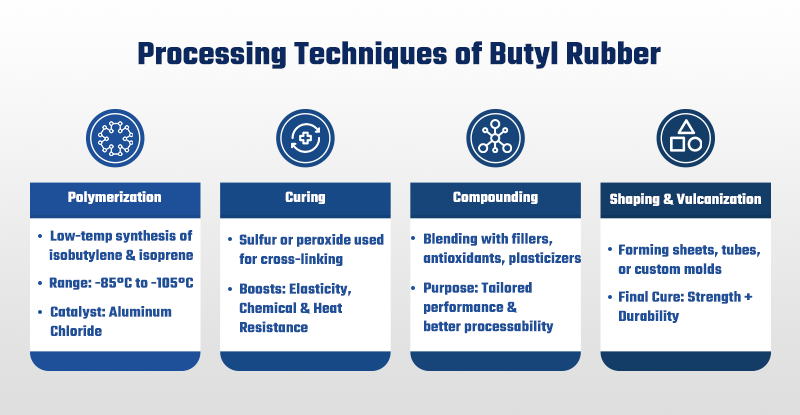

The process begins by polymerizing isobutylene with a small percentage of isoprene, using a catalyst like aluminum chloride at cryogenic temperatures of around -85°C to -105°C. This yields a copolymer with high impermeability and elasticity, critical for pressure-sensitive applications like inner tubes or gas seals.

The raw polymer is then cured using sulfur or peroxide systems. This introduces cross-links between the polymer chains, significantly improving the heat resistance, mechanical integrity, and chemical resilience of the material.

In this step, the base rubber is combined with specific additives to customize its properties:

This tailoring process allows manufacturers to produce butyl rubber optimized for everything from medical-grade closures to weather-resistant sealants.

The final stages involve molding or extruding the compounded rubber into the required form sheets, rings, or custom parts. These are then vulcanized (heated under pressure), locking in the desired performance characteristics such as elasticity and tensile strength.

The diverse attributes of butyl rubber make it valuable across a variety of industries in India:

As India continues its journey toward becoming a manufacturing powerhouse under initiatives like 'Make in India', butyl rubber is likely to become a material of choice in several fast-growing domains:

The shift toward electric vehicles (EVs) is accelerating demand for lightweight, air-retentive materials. Butyl rubber fits perfectly here, not just in tires, but also in seals and sound-dampening components used in EVs.

India’s expanding pharmaceutical and biotech sectors need reliable packaging and sealing solutions. Growth in biosimilars, vaccines, and medical devices will increase demand for high-purity butyl rubber.

With sustainability now a construction priority, butyl rubber’s energy-efficient insulation properties are being tapped for use in green-certified buildings.

There’s a rising emphasis on domestic production of synthetic rubbers to reduce import dependency. This will boost investments in butyl rubber manufacturing capacities within India, offering better cost efficiency and faster supply chains for local industries.

For businesses looking to integrate butyl rubber into their processes, here are important points to consider:

At Rajshila, we understand the growing complexity of India’s industrial landscape. With over 40 years of experience, we don’t just supply quality butyl rubber; we partner with clients to optimize its use across applications.

From technical consultation and compound customization to sustainable logistics and after-sales support, we’re here to help your business scale efficiently and responsibly. Whether you're producing high-performance tires or sterile pharma stoppers, Rajshila ensures that your materials deliver every time.

Butyl rubber is no longer a specialty material; it’s a strategic industrial asset. For Indian manufacturers looking to meet global standards in quality, performance, and sustainability, it offers unmatched value.

With a partner like Rajshila, your business gains more than just a supplier; it gains a material science ally dedicated to innovation, precision, and progress.