Megha Thakur 2025-11-21

Every pair of shoes tells a story, yet it is often the engineered layers inside that decide comfort, longevity, and style. In the bustling world of footwear, polyurethanes (PU) have quietly become the touchstone for advanced design, offering a unique combination of lightness, resilience, and adaptability. Rajshila’s journey across four decades sits at the heart of these innovations, connecting global expertise with the realities of the Indian consumer.

Polyurethanes, or PU systems, are the workhorses of contemporary footwear, transforming how soles cushion, flex, and endure daily use. Whether for athletic sneakers, rugged boots, or high-fashion sandals, PU’s versatility reigns. At Rajshila, we take a quiet pride in curating and advising on PU systems, each handpicked and refined for local and global needs.

What sets PU apart is its molecular structure. The clever interlinking of isocyanates and polyols gives rise to foams and elastomers that absorb impact, resist wear, and keep their bounce, all day long. PU’s contribution is woven into every sneaker’s bouncy comfort and every sandal’s feather-light feel.

Polyurethane (PU) systems are foundational to the modern footwear industry, delivering bespoke performance across applications.

Rajshila’s expertise ensures the right PU system choices tailored for superior footwear performance and evolving market needs, empowering brands globally with innovative, reliable solutions.

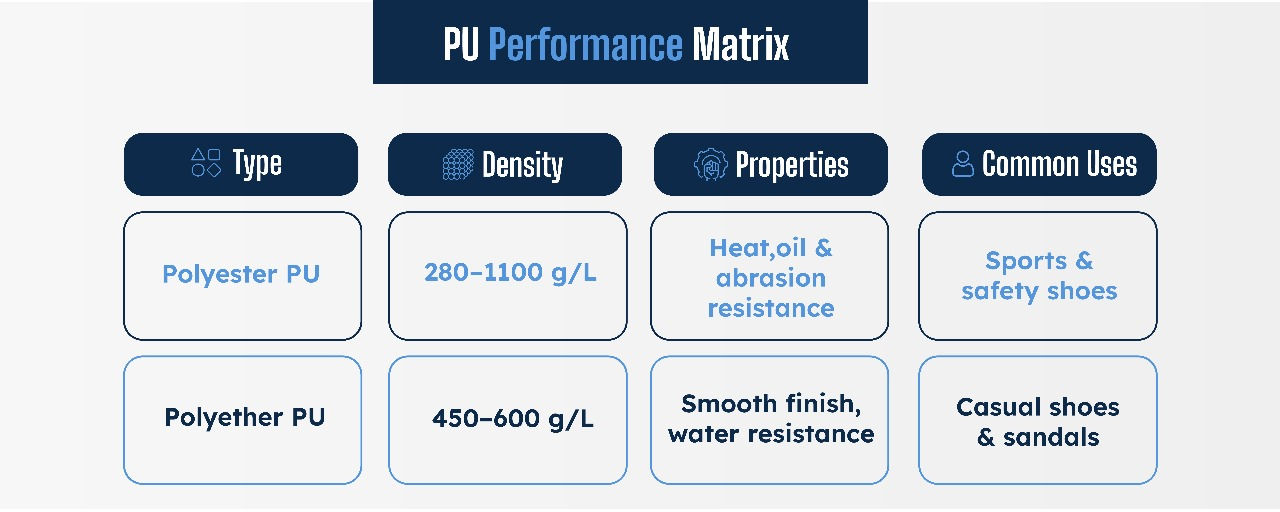

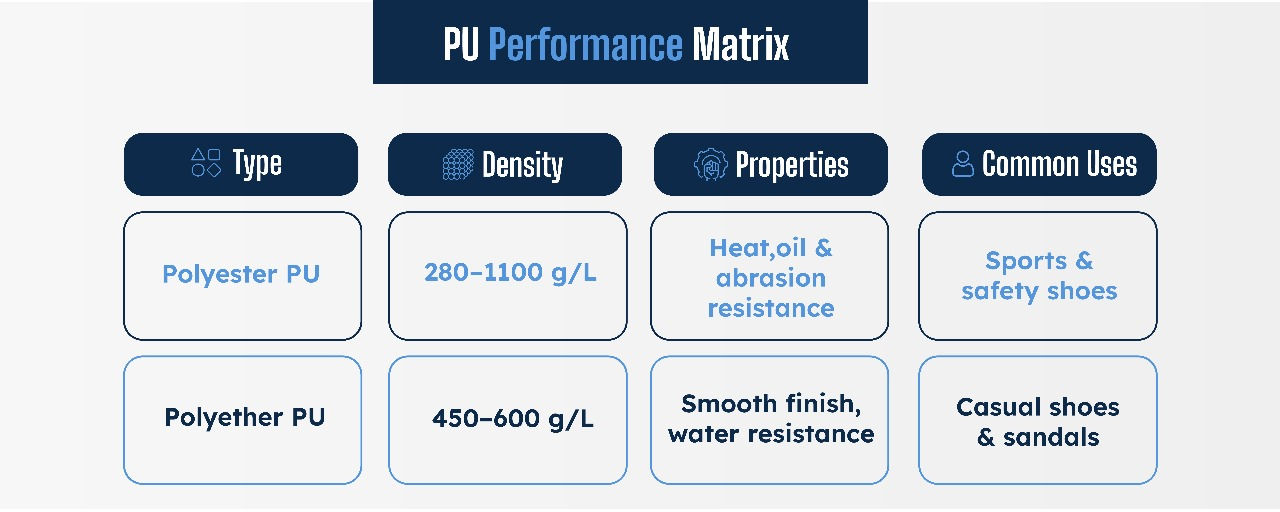

Within PU systems, two broad families, i.e., polyether-based and polyester-based polyurethanes, define most footwear applications. While both fall under the PU umbrella, their internal chemistry leads to very different performance outcomes on the ground.

Polyether PU is widely valued for its excellent hydrolytic stability, flexibility, and resistance to repeated compression. These properties make it especially suitable for footwear exposed to moisture, humidity, and continuous flexing, such as running shoes, school footwear, and everyday athletic styles. Its resilience helps maintain cushioning and comfort over long use cycles, even in demanding environments.

Polyester PU, by contrast, is known for its higher firmness and outstanding abrasion resistance. It is often chosen where shape retention, surface durability, and sharper structural definition are priorities, such as in soles that must retain crisp edges or withstand aggressive wear. However, this performance comes with trade-offs in hydrolysis resistance and long-term flexibility under wet conditions.

Understanding these distinctions is critical because the choice between polyether and polyester PU is not simply a matter of preference, but of aligning material behavior with real-world use conditions like load patterns, exposure to moisture, and expected lifecycle performance. In footwear design, these chemical differences directly translate into how a shoe feels, wears, and holds up over time.

Innovation is often a balancing act. Footwear must combine lightness with exceptional strength, and style with lasting comfort. Here, PU’s adaptability shines. Through technical partnerships, Rajshila supports brands in designing soles that minimize fatigue, while also resisting the stresses of heat, humidity, and urban grit. The science: precise catalyst blends, custom blowing agents, and process aids orchestrate the perfect foam structure, all curated through Rajshila’s industry partnerships.

International molds and component designs quietly find their way to Indian assembly lines, with Rajshila acting as a bridge, bringing global know-how home. It is this fine-tuned process management and troubleshooting where our expertise delivers greater value in quietly making better shoes a reality for millions.

Performance begins with selection, but comes alive in execution. Rajshila’s promise lies in more than premium material access; it is embedded in technical guidance, quality assurance, and hands-on integration. Reliable foam rise, consistent hardness, and uniform color; these are outcomes that result from rigorous attention to detail and a culture of continuous improvement.

Channel partners, often regarded as family, rely on our vast industry experience: from robust logistics to on-site troubleshooting, the journey is always collaborative. The impact of this quiet presence is felt in shoes that are comfortable, versatile, and last longer.

Sustainability is no longer a great addition; it’s what we owe to our future generations. Rajshila leans into this challenge, helping brands move to greener PU systems, advocate for closed-loop recycling, and choose catalysts and additives that minimize environmental load. As the world pivots toward more ethical footwear, Rajshila’s proximity to regulatory developments and eco-friendly chemistry becomes a subtle advantage for its partners.

Hybrid systems, biodegradable aids, and recycled content are all part of tomorrow’s footwear landscape, and Rajshila’s ethos positions it to navigate this evolving terrain and gently guide the industry forward.

Modern footwear is not just about comfort or stylistic innovation; it’s about intelligence: sensors, adaptive foaming, and personalized fits are all on the horizon. Our long-term perspective, honed through decades of problem-solving, translates to partners being ready for each leap. As trends shift and expectations grow, Rajshila stands not above, but rather right beside its partners, pushing for footwear that surprises, delights, and endures.

From marathon runners to school children, from high-heeled evenings to hiking adventures, our presence is humble yet foundational, knitting together ambition, expertise, and everyday comfort, day after day. Every comfortable stride, every durable sole, carries within it the legacy of thoughtful chemistry and partnerships. Rajshila continues to be the quiet force, transforming simple walks into journeys made memorable by science and care.