Akansha Sharma 2025-11-20

In the fast-evolving world of automotive engineering, every material choice echoes down the line, influencing everything from ride quality to global sustainability. Butyl rubber stands out in this landscape, not simply for its technical properties, but for its central role in redefining performance, safety, and efficiency. For decades, automotive manufacturers and component makers have relied on specialists like Rajshila to provide materials that aren’t just fit for purpose, but which push boundaries and respond to tomorrow’s mobility challenges.

Butyl rubber, technically known as isobutylene-isoprene rubber, is recognized industry-wide for a set of virtues perfectly suited to modern driving. Its remarkable air barrier property ensures tyres retain pressure far longer than traditional rubbers, supporting both safety and energy efficiency. Rajshila’s portfolio features butyl rubber sourced with an eye on uniform particle distribution, low cure-site impurities, and resistance to oxygen and ozone, ensuring longevity across seasons and geographies.

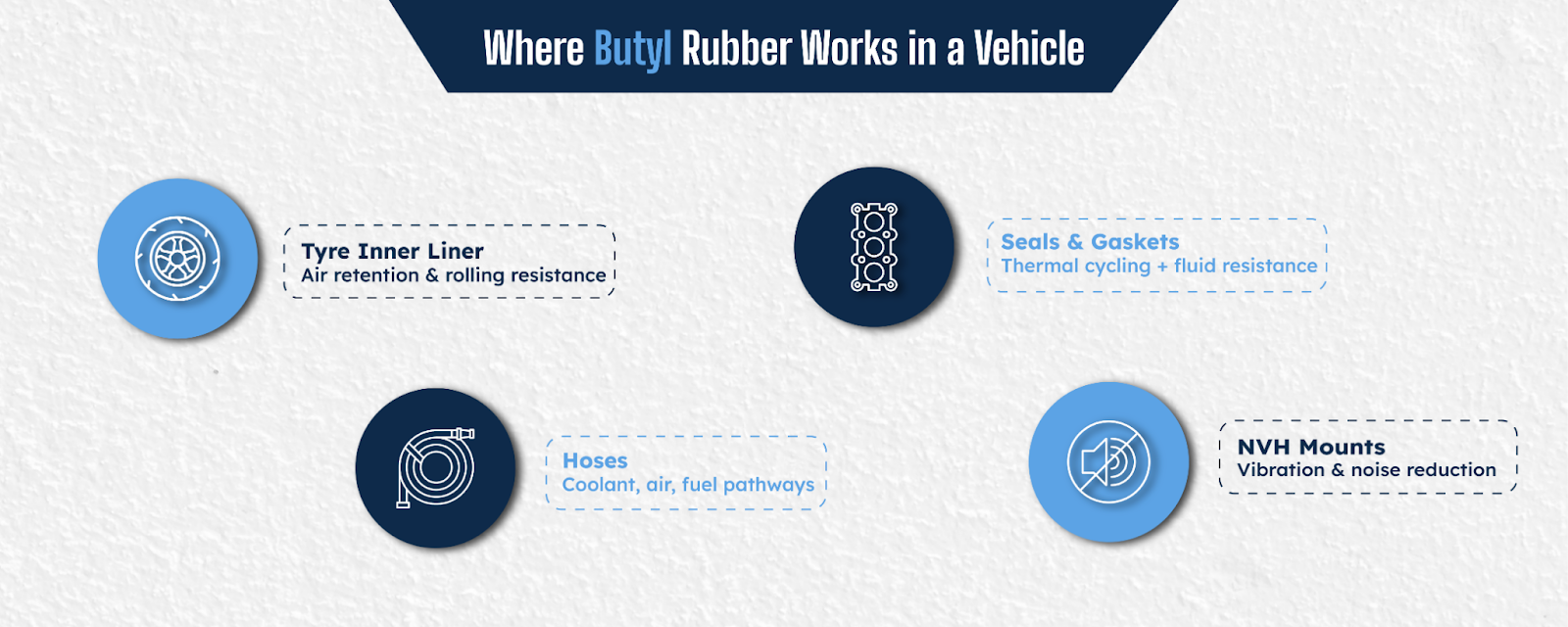

The combination of chemical inertness, high flexibility at low temperatures, and a low glass transition point makes butyl rubber the favourite for demanding applications such as tyre inner liners, weatherstripping, and vibration-dampening components. Our approach is rooted in working closely with automotive design engineers, offering guidance that combines on-the-ground experience with a strategic understanding of new mobility trends.

The backbone of every tubeless tyre is the butyl rubber inner liner. It is engineered to reduce air loss and, by extension, rolling resistance, which drives improved fuel efficiency. In an era of rising EV adoption and longer manufacturer warranties, consistent air retention is more critical than ever.

But the role of butyl rubber doesn’t end at the tyre. Its blend of elasticity and impermeability translates into essential automotive parts such as:

Our portfolio stands out for its adaptability. Our team partners with OEMs to adjust Mooney viscosity, antioxidant content, and cure profiles, so every batch integrates seamlessly into production lines that demand nothing less than perfect repeatability.

Performance isn’t a static target; it thrives on consistency, traceability, and technical adaptability. We ensure every lot adheres to international benchmarks for physical properties and is matched with comprehensive documentation for automotive quality audits. For manufacturers seeking specialized grades, such as low-ash butyl for emissions-compliance or custom-packed granules for high-efficiency mixing, Rajshila proves to be a reliable partner.

However, our partnership extends beyond product delivery. Our team consults on compound adjustments for applications as diverse as EV motor insulation to legacy fuel seals, helping solve technical challenges that arise in the field or the R&D lab. With 40 years of experience and a vast network of global collaborators, Rajshila delivers not just materials, but reassurance and forward-thinking technical insight.

The automotive industry isn’t standing still. Regulation on emissions and recyclability is tightening. The pivot to electric vehicles is redrawing the technical map, requiring superior temperature and electrical resistance from all elastomeric components. Our ongoing investment in new industry collaborations ensures the butyl rubber we bring to market is always ahead of the curve: formulated for use in high-voltage insulation, lightweight sealing systems, and even for next-generation “green” tyres with ultra-low rolling resistance.

With sustainability a priority, we help our partners discover butyl grades that incorporate recycled polymers, enabling compliance with global green standards and supporting clients’ own environmental commitments.

The future of automotive elastomers will be defined less by incremental improvements and more by how materials anticipate change in terms of new drivetrains, new regulations, and new expectations of sustainability. Butyl rubber’s role in that evolution is shifting from a dependable sealant to a material platform for smarter mobility. Its adaptability across EV battery insulation, low‑noise interiors, and lightweight, high‑efficiency tyres shows that performance is no longer limited to endurance; it’s about enabling the next wave of engineering ideas.

At Rajshila, we see this transformation as an opportunity to blend chemistry with foresight. By aligning advanced butyl rubber technologies with evolving design philosophies, we’re helping manufacturers reimagine what reliability can mean in clean, connected, and intelligent vehicles. In the quiet chemistry of butyl rubber lies the potential to make mobility stronger, safer, and more sustainable than ever.