Akanksha Sharma 2025-10-10

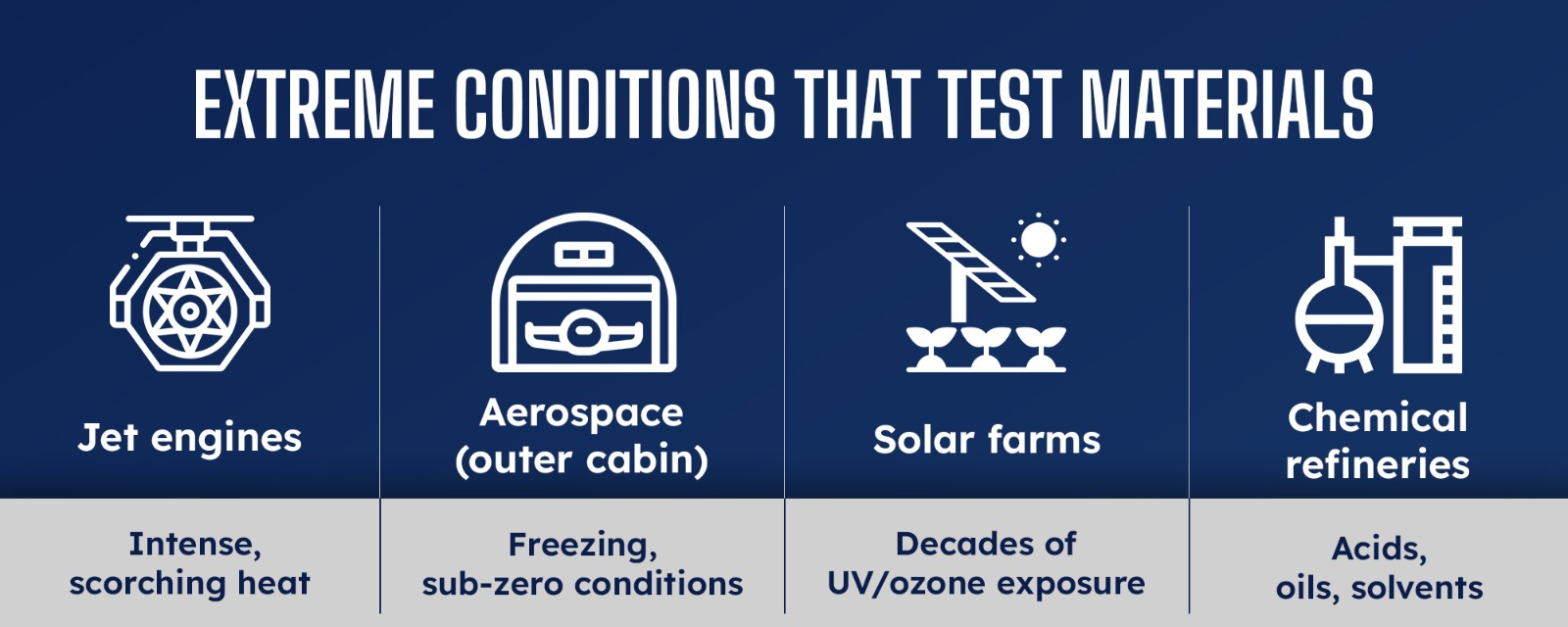

From the blistering heat inside jet engines to the ultra-sterile, high-pressure conditions of surgical theaters, from the relentless glare of desert solar farms to the corrosive atmospheres of chemical refineries, industries across the globe face one common challenge: surviving environments that push materials to their breaking point. Under such extremes, many substances lose their shape, weaken, or break down; impacting safety, reliability, and efficiency.

And yet, in the face of these unforgiving conditions, one material consistently stands strong, retaining its flexibility, resilience, and performance where others fall short: silicone rubber.

The secret to silicone rubber’s unmatched performance lies in its molecular backbone. Built on strong silicon-oxygen bonds, it has a stability and resilience that go far beyond conventional elastomers. In simple terms, this structure equips silicone to resist heat, cold, chemicals, and time in ways that few other materials can match. But what does this look like in the real world?

Aerospace & Aviation: At 35,000 feet, conditions are nothing short of extreme. Aircraft seals and components face subzero temperatures outside the cabin, sometimes as low as −50 °C, while simultaneously enduring engine compartments that can soar well above 200 °C. Ordinary materials would stiffen, crack, or deform under these shifts. Silicone, however, retains its elasticity and sealing properties across this vast temperature spectrum, ensuring not just performance, but passenger safety and operational reliability.

Healthcare: In hospitals, failure is not an option. Medical-grade silicone withstands repeated sterilization cycles, whether through high-pressure steam, radiation, or aggressive chemical cleaning, without losing its properties. Unlike many materials that degrade after constant exposure, silicone remains stable and biocompatible, making it the trusted choice for implants, catheters, prosthetics, and surgical tools that must interact safely with the human body over long periods.

Solar & Infrastructure: Modern infrastructure demands longevity. Roof membranes, expansion joints, and solar panel seals are expected to endure decades of punishing sunlight, ozone exposure, and weather extremes without compromise. Silicone’s natural resistance to UV radiation and oxidation means it doesn’t become brittle or break down easily, reducing maintenance costs and extending infrastructure lifespans, critical in large-scale renewable energy and construction projects.

Industrial Manufacturing: In chemical plants and refineries, the environment is a constant test. Seals and gaskets are exposed to oils, solvents, and corrosive chemicals that weaken most materials over time. Silicone’s chemical resistance allows it to maintain integrity in such settings, preventing leaks, minimizing downtime, and safeguarding worker safety.

Across these industries and beyond, silicone is more than just another material, it is a guarantor of uptime, safety, and confidence. When the stakes are high and environments unforgiving, silicone rubber consistently proves its worth as a material that doesn’t just endure, but excels.

While silicone rubber has long proven its value in seals, gaskets, and insulation, its potential today goes far beyond these traditional applications. Driven by technological innovation and evolving industrial demands, silicone is finding new roles in some of the fastest-growing sectors of the global economy.

Electric Vehicles (EVs): The transition to electric mobility demands materials that can withstand heat, electrical stress, and continuous operation under harsh conditions. Silicone rubber is stepping up as a key enabler. From battery pack seals to high-voltage insulation, silicone ensures safety and efficiency under fluctuating temperatures and exposure to coolants. Its stability makes it a vital enabler of the electric mobility revolution.

Wearables & Medical Devices: In healthcare and consumer electronics, comfort and safety are paramount. Liquid Silicone Rubber (LSR) allows precision micro-molding of soft, skin-friendly components. Whether in implants, surgical devices, or fitness wearables, silicone delivers biocompatibility and comfort with long-term durability. As the demand for personalized healthcare and lifestyle devices rises, silicone’s role only becomes more vital.

Soft Robotics & Automation: The world of robotics is rapidly moving beyond rigid structures. Flexible grippers and haptic devices depend on silicone’s unique balance of elasticity and strength, enabling safe, adaptable interactions in robotics and advanced automation. This blend of adaptability and robustness is positioning silicone as a cornerstone of automation and robotics innovation.

Sustainable Infrastructure: Sustainability isn’t just about building more, it’s about building smarter and longer-lasting infrastructure. Advanced silicone coatings and sealants are now extending the lifespan of critical infrastructure, like solar panels, wind turbines, and smart city assets by resisting UV, ozone, and weathering, reducing maintenance and waste.

This expansion is reflected in the market outlook. The global Liquid Silicone Rubber (LSR) market is projected to grow from USD 7.18 billion in 2025 to over USD 10.4 billion by 2035. Much of this growth is driven by healthcare, electric mobility, and electronics; sectors where performance, precision, and reliability cannot be compromised.

In short, silicone rubber is no longer just a reliable performer, it is an active enabler of the technologies shaping our future. From cleaner transportation to smarter cities and more personalized healthcare, silicone is helping industries build what comes next.

Every elastomer in Rajshila’s portfolio brings its own strengths:

Silicone rubber stands alongside other elastomers as a specialized option, expanding the toolkit for manufacturers to address environments where conventional materials may face limits by unlocking possibilities in high-heat, high-performance, and precision-driven applications.

At Rajshila, we understand that thriving in extreme environments requires more than access to materials, it requires trust, expertise, and guidance. As one of India’s leading polymer solution providers, we deliver high-quality silicone rubber designed to perform where other materials reach their limits.

What sets us apart is not only the material, but the supporting expertise; from advising on the right formulations to ensuring consistency in supply chains. By aligning innovation with dependability, Rajshila enables partners to adopt silicone rubber confidently, whether for breakthrough products or for scaling existing applications to global standards.

Extreme environments are only expanding as industries move into cleaner energy, smarter healthcare, advanced mobility, and deeper space exploration. In this landscape, silicone rubber stands out as the material that enables performance where failure is not an option. And with partners like Rajshila, India’s manufacturing ecosystem is not just keeping pace with this transformation, it is actively shaping it.

Read more: