Akanksha Sharma 2025-10-15

Automobiles today are no longer just machines; they are ecosystems of performance, comfort, and sustainability. It’s not only engines and steel that define today’s cars, materials play an equally big role. Polymers have become indispensable to modern automobile design, enabling lighter, stronger, and more efficient vehicles.

A 10% reduction in mass can boost fuel economy by 6-8%. As electric vehicles reshape mobility, polymers play a vital role in offsetting battery weight and ensuring sustainable performance. Today, cars typically incorporate 150-200 kg of plastics, accounting for nearly 15% of total weight, spanning interiors, exteriors, under-the-hood components, and EV systems. This foundational shift in materials sets the stage for how different markets, like India, are redefining their place in the global automotive landscape.

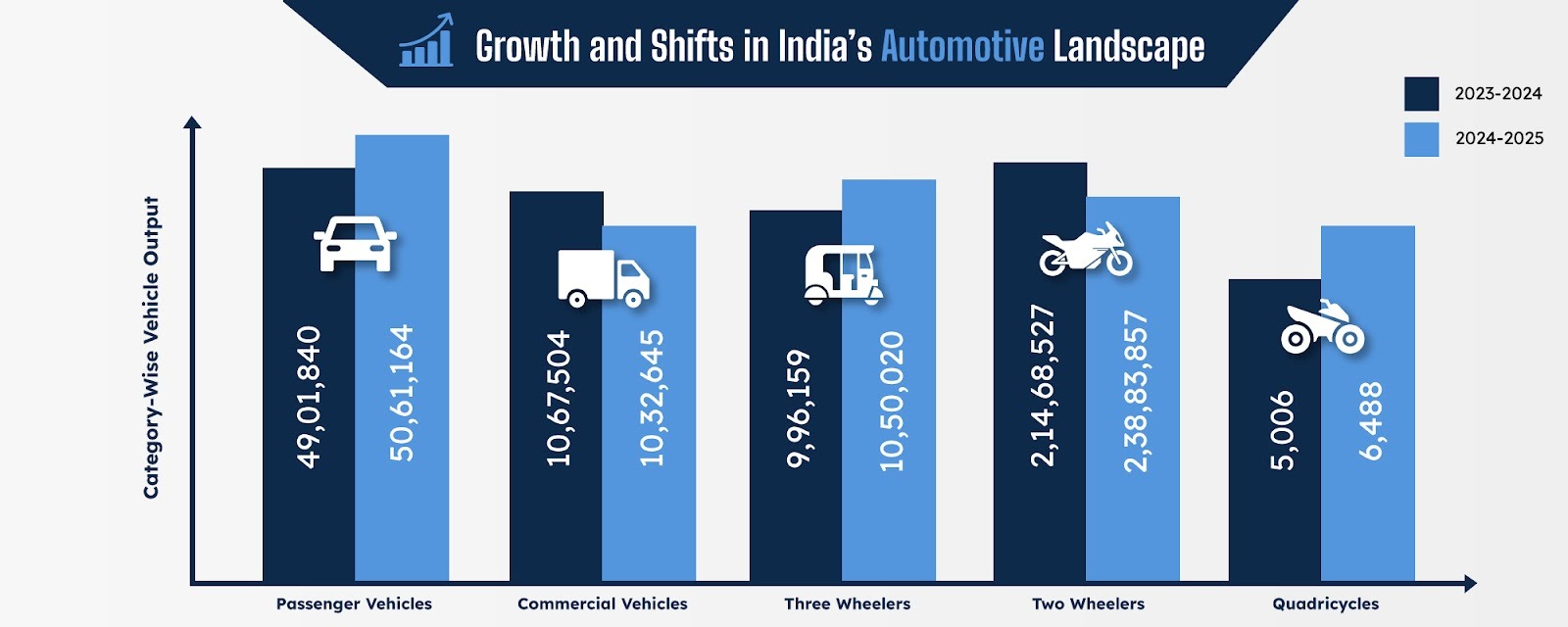

India is shifting gears in the global auto race, with production scale making it a heavyweight player at home and abroad. In the Financial Year 2023-2024, India manufactured around 29 million vehicles across all categories (two-wheelers, three-wheelers, passenger cars, and commercial vehicles), out of which nearly 4 million passenger cars were bought by Indian consumers. This scale makes India not only a major domestic market but also an influential player in global supply chains.

With rising domestic demand and a growing export footprint, the materials that go into cars matter more than ever. The focus is shifting from sheer output to smarter, more sustainable manufacturing. Polymers give India’s manufacturers a powerful edge: lighter, stronger, and easier to process than metals, they improve efficiency and cut costs. As India’s auto sector scales up, smart material choices like polymers could define its journey from a volume player to a value leader. This growing influence raises the question: what role can advanced materials, such as polymers, play in making India’s auto sector more efficient and competitive?

The rise of polymers in mobility is no accident; they deliver clear wins on efficiency, safety, and design. In terms of efficiency, incorporating polymers in place of some metal components can reduce vehicle mass, improving fuel economy by 6-8% for every 10% weight reduction, or 4-5% without powertrain downsizing. For EVs, this translates into extended driving range or smaller, lower-cost batteries.

On safety, polymers excel at energy absorption and controlled deformation, supporting crumple zones and producing shatter-resistant glazing and lighting. In design, their flexibility allows complex geometries, integration of features, and mold-in-color finishes, minimizing secondary operations and reducing costs. This synergy of performance, protection, and creativity positions polymers at the core of automotive innovation. These advantages only become more significant when we examine the specific polymers that form the backbone of modern cars.

Behind every sleek curve and smooth ride lies a network of advanced polymers that quietly power automotive innovation. More than 70% of automotive plastics come from four key families: polypropylene (PP), polyurethane (PU), polyamides (PA), and polyvinyl chloride (PVC), each with distinct strengths.

PP is the workhorse of exteriors and interiors, delivering lightweight durability in bumpers, dashboards, trims, and battery housings. PU foams bring comfort and durability to seats, headrests, and noise-vibration-harshness parts. PVC finds use in door panels, wiring insulation, and coatings, thanks to its chemical resistance and abrasion strength. Under the hood, PA 6/6 handles heat and oil in housings and connectors. High-performance ABS and PC/ABS ensure stable, impact-resistant interior trims, while PC is the go-to for crystal-clear, heat-resistant lighting lenses.

Elastomers and silicones seal, protect, and insulate components in high-heat zones like engines and e-motors. For cutting-edge designs, composites such as carbon and glass-fiber reinforced polymers deliver strength without the weight. While each material brings something unique, together they define how modern cars look, feel, and perform. Once understood at the material level, the real story emerges in how these polymers are applied across every vehicle system.

Polymers are central to modern vehicle performance, shaping comfort, safety, efficiency, and design. In cabins, they enhance ergonomics, noise reduction, and interior styling. On the exterior, lightweight, durable polymers help streamline vehicle assembly while enabling aerodynamic and aesthetically pleasing designs. Safety systems rely on precision-moulded components to absorb energy, protect occupants, and meet stringent crash standards. Under the hood, engineered plastics and composites withstand heat, oils, and vibrations, simplifying assembly and reducing weight. In Electric Vehicles (EVs), polymers and composites take on an even greater role; lightweight battery enclosures, thermal management components, and electrical insulation help extend driving range, improve efficiency, and maintain safety standards. Their versatility is especially critical in EVs, where added battery weight makes lightweighting an urgent priority.

One of the biggest challenges in the shift to electric mobility is weight, batteries make EVs heavier than ICE models. Battery electric vehicles (BEVs) typically weigh more than comparable internal combustion models due to the mass of lithium-ion batteries. This added weight affects range, braking, tire life, and even crash performance. Polymers and composites are rewriting the equation. By replacing heavier metals in body panels, underbody shields, and structural parts, with lightweight plastics and composites, automakers can cut weight and improve efficiency. These materials also simplify designs, allowing parts to be integrated instead of assembled in multiples. For EV batteries, advanced polymers provide fire resistance, insulation, and thermal management. In short, polymers make electric vehicles not just cleaner but lighter, safer, and more practical for everyday use. But solving the EV challenge is not just about weight savings; it also connects to how cars are designed for end-of-life and recycling.

The automotive industry is entering a new era of circular design, with policies like the EU’s End-of-Life Vehicles directive setting the pace. Under the EU’s End-of-Life Vehicles proposal, cars must include at least 25% recycled plastics, partly recovered from ELVs. This creates momentum for recyclable polymers, mono-material construction, and chemical recycling pathways for mixed streams. By embedding traceability and disassembly at the design stage, policy is transforming materials into the foundation of a truly sustainable automotive ecosystem. Meeting these ambitious goals requires material partners who can bridge innovation, compliance, and scalability.

The future of mobility won’t be defined by a single breakthrough material, but by how automakers combine performance, safety, cost, and sustainability in every component. At Rajshila, this systems-level view of material innovation has guided us for over 40 years. With 400+ solutions spanning natural and synthetic rubbers, polymers, fillers, activators, colourants, plasticizers, tackifying agents, curatives, silicone emulsions, mold release agents, specialty chemicals, PU systems and more, we see materials not as commodities but as enablers of design freedom, lightweighting, and efficiency.

For India’s auto sector, the real advantage lies in making smarter material choices, and Rajshila is helping manufacturers get there. Our end-to-end supply model—with direct sourcing, strategic inventory, and streamlined logistics—means automotive clients get fast, reliable access without opaque intermediaries. Whether it’s lightweight interiors, durable under-hood components, or sustainable polymer formulations, Rajshila empowers automakers with the right material mix and expert support for scale. By aligning performance, safety, cost, and sustainability, Rajshila helps manufacturers stay ahead in a sector where materials are the new competitive advantage.

The next phase of mobility will be defined not just by electrification or connectivity, but by the materials that hold every part together. Polymers offer automakers the rare balance of lighter cars that still meet safety demands, deliver comfort, and reduce costs. As India grows into a global auto powerhouse, material choices will define progress. With Rajshila’s expertise and range, automakers gain a partner who helps them build smarter, greener vehicles designed to match international benchmarks and advance toward a sustainable future. With Rajshila as a trusted partner, Indian automakers can engineer lighter, smarter, and greener vehicles, shaping the country’s path toward global leadership in sustainable mobility.

Read more: The Role of Polymers in the Modern World