Megha Thakur 2025-09-24

Footwear is no longer just about covering and protecting feet. Today, every shoe is expected to deliver comfort, durability, performance, and sustainability; all at once. At the heart of this transformation lies material innovation. The right material choices can redefine cushioning, improve energy return, reduce weight, and even lower environmental impact.

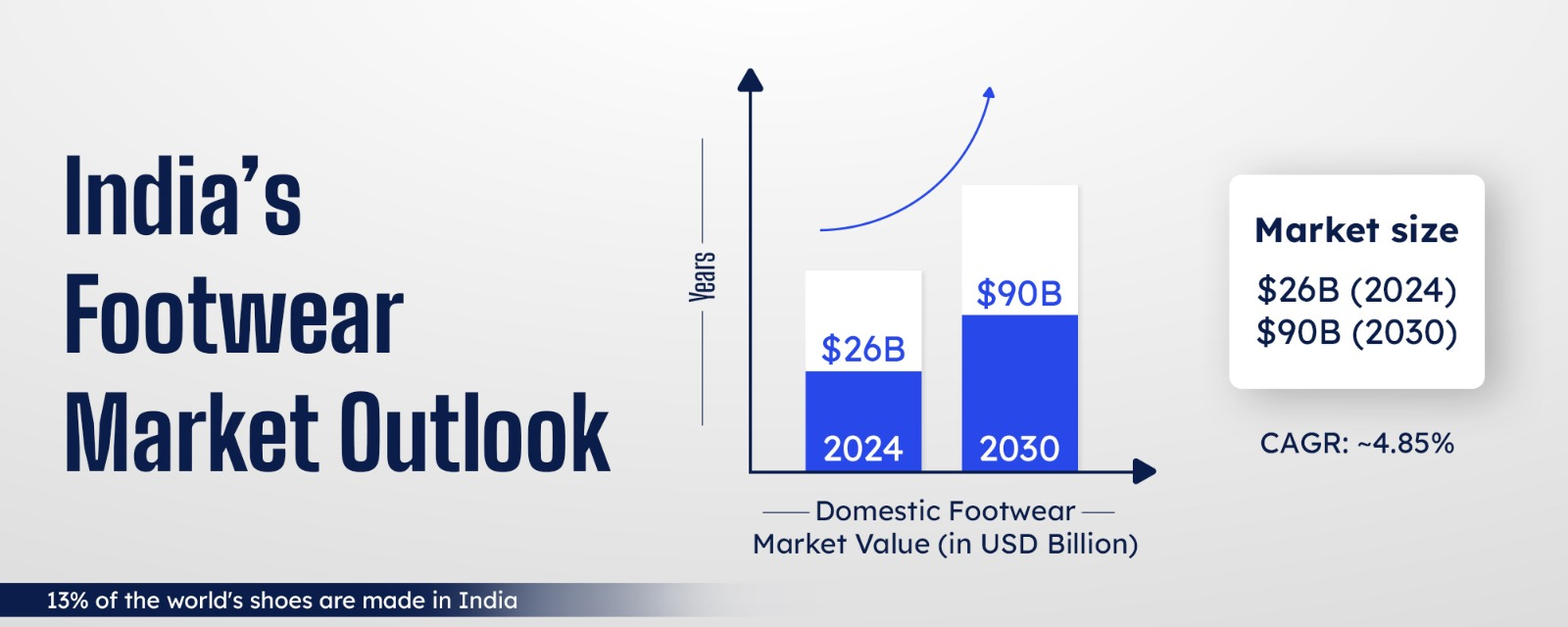

As the world’s second largest footwear producers, India is uniquely positioned to harness these innovations. Currently valued at $26 billion, the domestic footwear market is set to reach USD 90 billion by 2030 and with a young, fashion-conscious consumer base, the opportunity is vast. At Rajshila, we see this as a pivotal moment for the industry, where advanced polymers, bio-based materials, and proprietary foams reshape how shoes are designed and manufactured.

Every component of a shoe–the midsole, outsole, insole, and upper–is a story of material science. Traditional materials like leather and rubber are giving way to engineered polymers, advanced foams, and sustainable alternatives. The global footwear sole materials market alone is projected to expand from USD 23.65 billion in 2025 to USD 30.46 billion by 2030, reflecting how critical this sector is becoming.

The focus is clear: lighter, stronger, and smarter materials that enhance both design and performance. Rajshila is at the forefront of this revolution, supplying materials that support innovation across the entire shoe lifecycle.

The backbone of today’s footwear lies in engineered materials that deliver comfort, durability, and performance. Ethylene-vinyl acetate (EVA) continues to power mass-market footwear segments with being a preferred choice for Hawai chappals and slippers, offering abrasion resistance, affordability, and design flexibility. Polyurethane (PU) systems provide superior cushioning and wear resistance, while Thermoplastic polyurethane (TPU) adds toughness and sleek finishes to soles. Together, they enable manufacturers to craft shoes that combine comfort, aesthetics, and long-lasting performance.

Alongside these, thermoplastic rubber (TPR) with flexible, durable soles; deliver high performance with excellent grip and resilience. Combining the processing ease of thermoplastics with the strength of rubber, TPR is used to make soles that are tough yet comfortable. Its recyclability and consistent quality make it a reliable choice for a range of footwear. Polyvinyl chloride (PVC) offers excellent abrasion resistance and design flexibility, making it suitable for sandals, casual shoes, and affordable footwear segments. Its durability ensures products stay in use longer, even in tough conditions. With the increasing demand for non-leather, sustainable alternatives, artificial leather provides durability and moisture resistance with strong, flexible, and leatherlike finishes.

This integrated materials ecosystem allows manufacturers to select tailored solutions for every category, from mass-market slippers to premium performance footwear.

Sustainability has become one of the strongest forces shaping the global footwear industry. Consumers and regulators alike are demanding eco-friendly materials, pushing brands to adopt natural rubber, plant-based EVA, recycled plastics, and vegan leathers. The bio-based midsole material market is projected to nearly double from USD 786.4 million in 2024 to USD 1.64 billion by 2033, with Asia Pacific leading adoption. Yet, scaling these innovations remains a challenge due to higher costs, performance validation, and limited recycling infrastructure.

At Rajshila, we actively support this shift by offering a broad portfolio, including polymers, natural and synthetic rubbers, plasticizers, colouring agents, mould release agents, and performance enhancers. Our solutions are designed to help footwear manufacturers balance durability, efficiency, and environmental responsibility. With expertise in polyurethane (PU) systems, EVA grades, silicone-based agents, and speciality additives, we enable partners to meet evolving market demands without compromising on performance. Backed by decades of technical knowledge and reliable supply, Rajshila bridges the gap between global innovation trends and practical, scalable solutions for India’s footwear industry.

Foam innovation has become the defining battleground in performance footwear. Proprietary foams engineered for energy return, responsiveness, and durability are setting new benchmarks in energy efficiency and rebound. Lighter midsoles with superior responsiveness have been proven to enhance athletic performance, making cushioning technology a key differentiator for global brands.

Rajshila brings similar innovation to Indian footwear manufacturing with advanced lightweighting and cushioning solutions. Our Expancel® expandable microspheres reduce midsole weight while enhancing rebound and providing smoother finishes. Paired with our EVA grades, PU systems, TPU resins, and TPR compounds, these materials enable manufacturers to deliver midsoles that are lightweight, durable, and globally competitive. From athletic shoes requiring high energy return to casual footwear demanding everyday comfort, Rajshila’s solutions help Indian brands create next-generation foams that meet international performance benchmarks.

India already contributes 13% to global footwear production and is steadily becoming a China+1 manufacturing hub. While leather has traditionally dominated, non-leather segments such as sports shoes, sneakers, and athleisure footwear are projected to capture 75% of the market by 2030.

Material innovation is at the heart of India’s footwear industry transformation. The rapid growth of e-commerce platforms has fueled demand for diverse and premium footwear, while the country’s youth demographic increasingly gravitates toward stylish, non-leather, and performance-oriented products. At the same time, government initiatives, such as BIS compliance regulations and the development of footwear parks in Tamil Nadu, are strengthening India’s manufacturing competitiveness. With ready access to polymers like EVA, TPU, PU, TPR, PVC, and Artificial Leather, alongside a growing focus on sustainable raw materials, India is well-positioned to emerge as a global leader in innovative footwear production.

As a trusted solutions partner, Rajshila is committed to advancing material innovation in footwear. Our portfolio spans EVA grades, PU systems (DALTOPED®), Avalon® TPU, and TPR compounds; complemented by plasticizers, silicone emulsions, mold release agents, and specialty additives that improve processing and durability. With more than 400 products and decades of expertise in polymers and performance materials, we work closely with manufacturers to enable scalable adoption of cutting-edge solutions. By combining reliable supply with technical know-how, Rajshila helps the Indian footwear industry move toward smarter, lighter, and more sustainable designs that meet global benchmarks.

The future of footwear will be defined by how materials can balance performance with responsibility. From super foams that propel athletes forward to bio-based compounds that reduce environmental impact, innovation is shaping every step we take.

India, backed by its strong manufacturing ecosystem and forward-looking suppliers like Rajshila, is perfectly positioned to lead this transformation. The path forward isn’t just about making better shoes, it’s about shaping a better future for the industry and the planet.

Source: https://gtri.co.in/DisplayFlagshipReports.aspx?ID=28&

https://dataintelo.com/report/bio-based-shoe-midsole-material-market

https://www.mordorintelligence.com/industry-reports/footwear-sole-material-market