Megha Thakur 2025-11-10

While it’s easy to imagine the future of automobiles being driven by modern propulsion systems, sleek designs, and advanced self-driving technology, the real revolution is happening inside the materials that hold everything together. Beneath the metal panels and circuits lies a complex network of rubber components in the seals, gaskets, hoses, dampers that often go unnoticed but play a vital role in vehicle safety, performance, and durability. These rubber compounds are a core part of automotive innovation, and today, advanced solutions enabled by Rajshila are central to transforming this critical element for tomorrow’s mobility.

The Rising Curve: Why Smarter Materials Are in Demand

Modern vehicle manufacturers are continuously rewriting the blueprint of mobility. With increasing demands for lightweight, durable, and eco-conscious materials capable of handling higher heat loads, stress, and design complexity, the role of advanced elastomers has never been more important. Market insights project advanced elastomers demand to exceed USD 46 billion by 2030, powered largely by the rise of electric and hybrid vehicles.

In regions like Asia-Pacific where electric vehicles are rapidly growing, Rajshila enables the integration of high-performance elastomers such as silicone rubber, EPDM, and fluoroelastomers. These materials offer crucial benefits for battery insulation, vibration control, and under-hood applications, enhancing not just the mechanics but also the safety and sustainability of vehicles. This symbolizes the constant evolution of rubber from a passive material to a dynamic driver of automotive progress.

Role of Rubber in Automobiles and Choosing the Right Materials

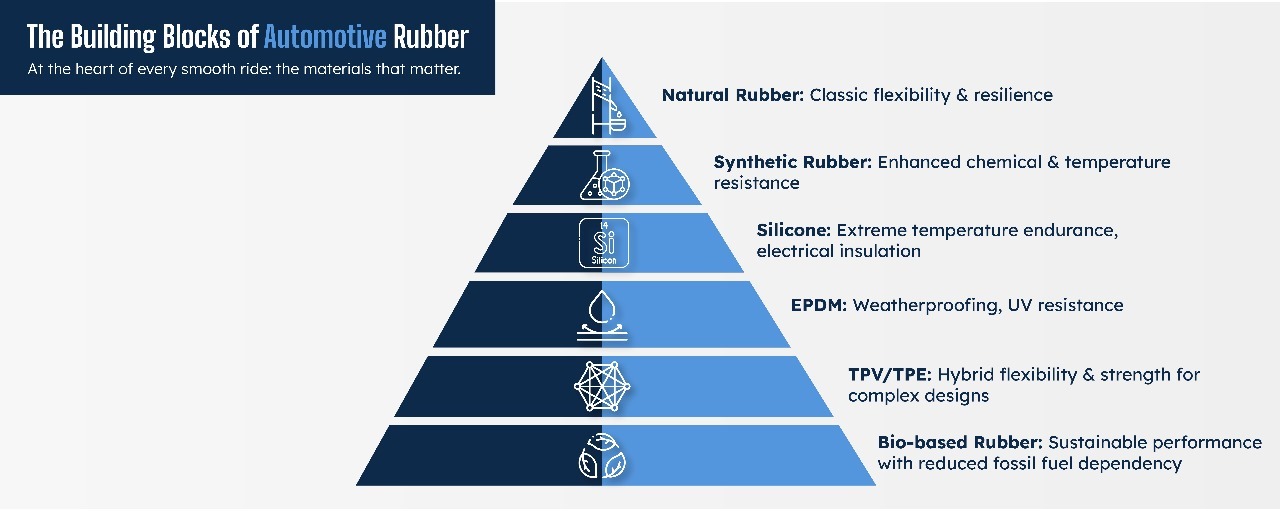

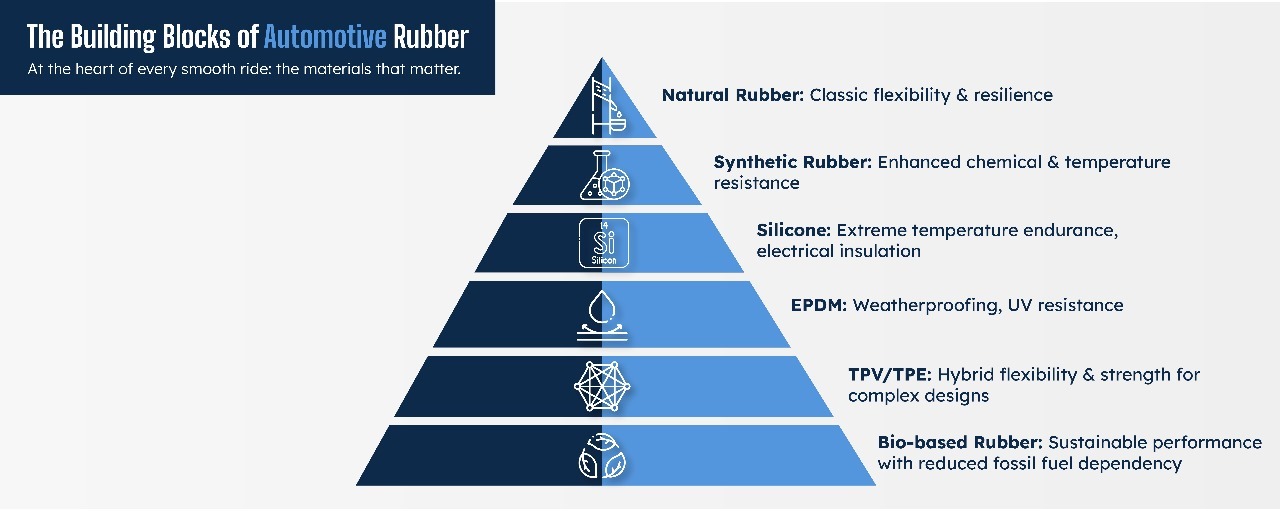

Rubber’s presence in automobiles spans an impressive range of applications, each with its own material demands. Rajshila’s product portfolio covers these extensively, helping manufacturers select the right rubber types for their specific needs:

Rajshila’s extensive catalog reflects an intricate understanding of these materials. Beyond providing options, we help partners navigate through material properties, applications, and compatibility, ensuring each rubber compound contributes effectively to vehicle performance and longevity.

The Road Ahead: Embracing Innovation and Sustainability

The automotive future is being shaped by innovations that once seemed distant: smart elastomers capable of sensing wear, self-healing minor damages, or even conducting electricity may soon enable smarter, safer vehicles. Seals that communicate their condition before failure, vibration mounts that adjust dynamically; these visions, once just in labs, are moving closer to reality aided by advanced material science.

Sustainability drives a parallel transformation. Circular manufacturing practices aim to turn every component into a resource, not waste. Rajshila actively supports this shift through the development of bio-based rubbers and chemical recycling processes like devulcanization. Such approaches breathe new life into worn components, promoting reuse without compromising quality, a crucial step in reducing the automotive industry’s environmental footprint.

Rajshila stands at the nexus of chemistry, collaboration, and computation. Its broad portfolio spanning natural and synthetic rubbers, fillers, and specialty additives forms the building blocks of automotive rubber innovation. Coupled with close partnerships across the supply chain, Rajshila helps bring these materials from lab to production floors, combining deep formulation knowledge with emerging technologies like digital twins and AI-driven predictive maintenance. This empowers automakers and component makers to reduce waste, accelerate development, and build reliability into every part.

As the push for zero emissions and flawless manufacturing grows stronger, the unassuming rubber beneath your vehicle’s surface will define the limits of progress. And through it all, Rajshila continues its quiet mission, strengthening the invisible core that drives the future of mobility, one molecule at a time.