Megha Thakur 2025-08-20

In rubber and plastic compounding, material quality is a defining factor in final product performance. Among the range of additives used, zinc oxide holds a central position due to its chemical versatility and functionality. Its role extends far beyond being a filler, it acts as a key enabler in achieving strength, stability, and durability in diverse polymer systems.

Used across industries from automotive to packaging, zinc oxide continues to prove indispensable in compounding.

Rajshila, with over four decades of experience, has been instrumental in supplying industry-specific zinc oxide to ensure consistency and application precision.

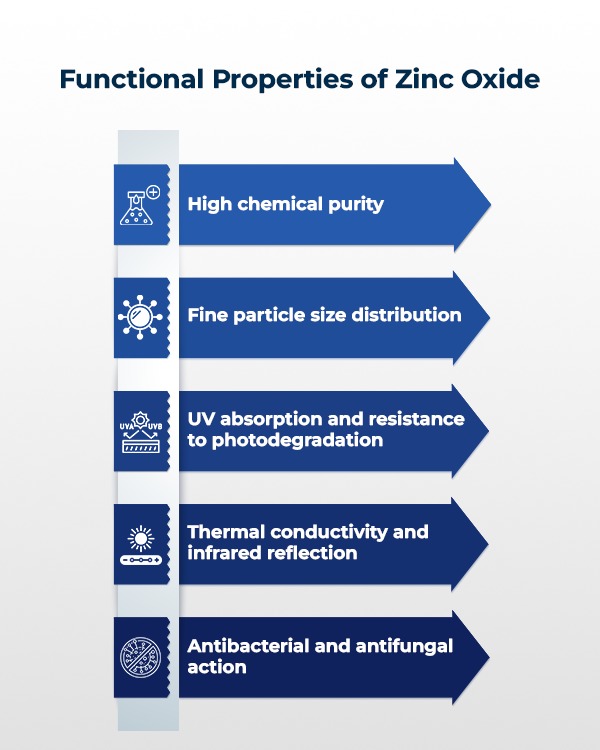

Zinc oxide (ZnO) is a white, inorganic compound known for a wide spectrum of material-enhancing characteristics:

These intrinsic zinc oxide properties enable its extensive use across various domains, including rubber vulcanization, plastic stabilization, ceramics, pharmaceuticals, coatings, and agriculture.

Zinc Oxide in Rubber Compounding

Zinc oxide is a critical activator in sulfur vulcanization systems used in rubber processing. It facilitates the formation of cross-links, thereby enhancing the mechanical and thermal properties of the final compound.

Its functions in rubber include:

For consistent curing and uniform physical properties, manufacturers often prefer zinc oxide with controlled particle morphology.

Zinc Oxide in Plastic Compounding

In plastics, zinc oxide functions primarily as a stabilizer and UV absorber. It plays a significant role in improving product longevity, especially in outdoor and high-temperature applications.

Applications include:

Rajshila, supplies fine zinc oxide tailored for various rubber applications, including tires, footwear, conveyor belts, and molded goods. Our product range supports clients in achieving predictable results even in complex compounding processes.

Read more: A Mistake Manufacturers Make When Buying Zinc Oxide

The global zinc oxide market is forecasted to witness robust expansion, with its size projected to rise from USD 9.5 billion in 2024 to nearly USD 16.7 billion by 2034, reflecting a steady CAGR of 5.8% during this period. Due to its critical role in enhancing the durability, elasticity, and heat resistance of rubber products, zinc oxide continues to be a vital component in the industry. In fact, the rubber sector alone accounted for approximately 43.2% of the zinc oxide market in 2024, underlining its significance in tire manufacturing and other elastomer-based applications.

The Asia-Pacific region dominated the global landscape with a commanding 51.2% share, valued at about USD 4.8 billion.

This upward trend is also supported by increased interest in sustainable and naturally derived ingredients. In cosmetics, zinc oxide’s non-toxic, UV-blocking nature has made it a favored choice for eco-conscious sunscreen formulations. Meanwhile, investment opportunities are growing in expanding production capabilities especially in Asia-Pacific, where ongoing industrialization continues to boost demand.

Furthermore, emerging uses such as zinc oxide nanoparticles in electronic components and energy storage systems offer exciting new avenues for innovation. Technological advances including solar-powered production methods and low-emission processes not only reduce environmental impact but also promise long-term cost savings.

The push for sustainable and performance-optimized materials has led to innovations in zinc oxide manufacturing. These include:

Zinc oxide is more than a supporting component in rubber and plastic formulations, it is a critical input that directly affects performance, durability, and compliance. As environmental regulations tighten and application demands evolve, the quality and reliability of zinc oxide will continue to shape formulation strategies.

Rajshila, through its application-centric approach, believes that the future of zinc oxide lies in precision engineering, optimizing every particle to meet the nuanced needs of modern materials.

Looking to enhance your compounding formulations with application-specific zinc oxide? Partner with Rajshila, a trusted supplier of high-performance zinc oxide solutions.

Reference Links:

https://www.citracakralogam.com/zinc-oxide-in-rubber-industry-formulations-manufacturing/

https://www.zinc.org/

https://pmc.ncbi.nlm.nih.gov/articles/PMC9737580/

https://en.wikipedia.org/wiki/Zinc_oxide

https://www.zochem.com/advanced-zinc-oxide-for-the-plastics-industry/

https://polymeradd.co.th/zinc-oxide-use-and-applications-in-plastics-and-polymers/

https://www.news.market.us/zinc-oxide-market-news/

https://pmc.ncbi.nlm.nih.gov/articles/PMC5453364/#sec12